Recent changes in legislation have opened many new opportunities for cannabis research. The FDA will support the scientific research needed to develop new drugs from cannabis. The FDA’s drug approval process and regulation are the best way to ensure the safety and effectiveness of any drug containing or derived from cannabis compounds. Currently, thousands of companies are selling products that contain CBD without FDA approval. It is unprecedented for an active pharmaceutical ingredient to be available to the general population without FDA approval. The FDA has only approved the use of cannabinol (CBD) for a medication called Epidiolex, which is used to treat certain forms of epilepsy.

Cannabis products with .3% or less of tetrahydrocannabinol (THC) are legal at the federal level. Anything above .3% is illegal. Regulation is essential to the growth of the cannabis market. There needs to be regulation to test, standardize, manufacture, label, and quality control cannabis products.

People are growing cannabis with no idea of what strains to grow, how to manage pests, soil and most importantly, when to harvest.

Extractors are operating without any process control programs or scientific knowledge. Without a method and proper quality control, they have no reproducibility. Studies have proven that without control, consumers are purchasing CBD products that contain significantly less CBD than stated on the packaging. Some products tested did not contain any CBD at all. This leads us to the conclusion that patients are not getting the correct dose of medication. Mislabeling is a serious concern and the reasoning behind why regulation is important. This is why traditional drugs need FDA regulation.

The FDA may also offer assistance in regulating inner laboratory error. These errors are due to lack of standard analytical methods, materials, and training. Many farmers, growers and processors do not have testing equipment so they hire third party cannabis testing laboratories. By the time a grower gets the results back, they risk losing their entire crop. Harvesting time is critical. In many jurisdictions if the crop exceeds .3% cannabinoids the entire crop needs to be destroyed. Most growers do not have technical expertise or an analytical chemistry or chromatography background. Therefore, they need a portable hemp and cannabis potency analyzer. One that is based on HPLC and has the same analytical performance and sensitivity as a laboratory-based instrument. HPLC is the only simple, easy, user-friendly method that works effectively. While other techniques produce a result, none of them offer the sensitivity, accuracy, reliability, and reproducibility that HPLC does. If challenged in a court of law, HPLC is the acceptable technique. All certified labs that are testing cannabis and hemp potency are using HPLC. It is the gold standard for potency testing.

When it comes to extraction equipment, we offer breakthrough extraction and purification technology. This unique technology is a natural extraction solution. Low pressure extraction technology combines unprecedented extraction methods based on tetrafluoroethane (TFE). TFE is a technique that has been overlooked in the industry. TFE’s are very inert and leave no residue because they only decompose under extreme conditions.

- TFE’s are lower costs because they are produced in high purity on a large scale

- TFE’s have much less degradation of materials because they have a higher polar solvent than CO2 at low pressures

- TFE’s yield significantly better extraction results for sensitive natural products

- TFE’s critical pressures and temperatures are much lower than carbon dioxide

- TFE’s can be more selective reducing additional steps that are necessary with CO2

- Result is significantly less capital and operational cost

After cannabis or hemp is extracted, we offer several options for your final purification.

Flash chromatography has the lowest CapEx. Icon Scientific offers systems that can purify kilograms worth of material. These systems can also handle preparative HPLC columns in addition to the Flash columns. HPLC offers higher resolution than Flash, but at a higher cost.

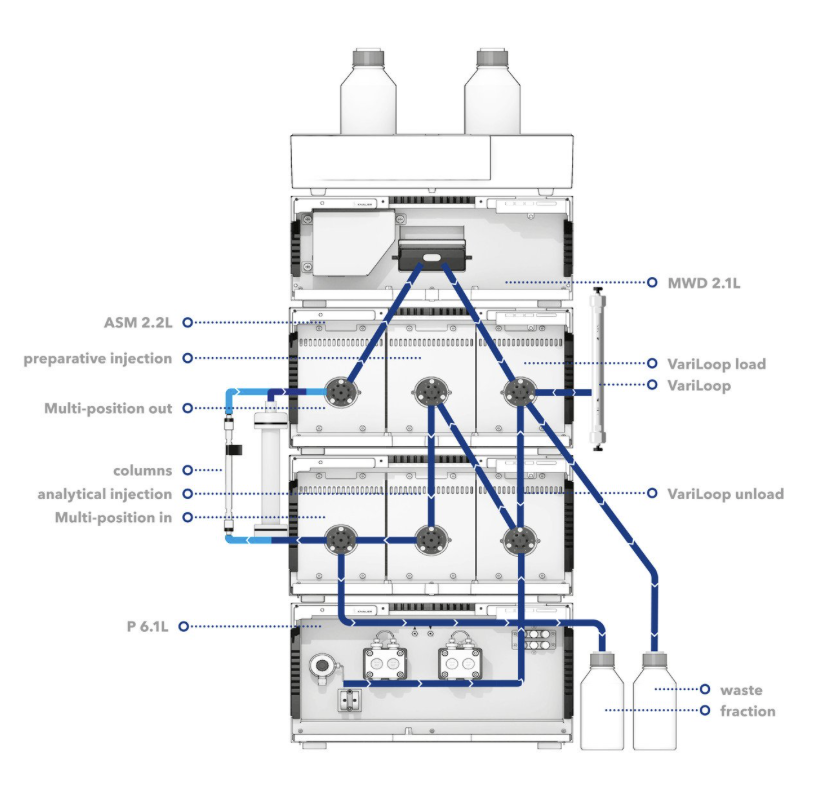

Preparative HPLC systems with capabilities up to 4 liters per minute are available. These systems are capable of processing up to 20 kilos of material per day. Multiple systems can be set up in tandem. This would provide an economical scale-up opportunity. This would also offer redundancy so that when one system needs maintenance, the other systems are still producing product.

CPC is another option for purification. CPC stands for Centrifugal Partition Chromatography. The CPC unit is used in a preparative HPLC system as the column. In CPC, both the stationary phase and the mobile phase are liquids. The benefit is higher purity compared to traditional HPLC and no purchase or disposal of solid phase resins.

The CapEx for these systems is higher than traditional HPLC systems but the operating costs are substantially lower. Our most popular system consists of a 12-liter CPC unit combined with a one liter /min quaternary pump, UV detector, a fraction collector valve and software. While these systems cost more to purchase, their actual costs overtime is less than any competing technology.

If all this sounds a bit confusing, it is! Icon Scientific is here to help. We can evaluate your individual needs and offer recommendations, so that you can select the best solution for your individual needs.